Iron Ore Crusher Grizzly

IFE Heavy-Duty Grizzly Feeders - Mining Technology

Applications for IFE grizzly feeders vary from chromate ores, iron ores, aggregates to CD waste. They are also capable of handling the highest capacities. Feed material with sizes

learn more

Comminution and classification technologies of iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

learn more

Jaw Crusher - ScienceDirect

2016年1月1日 Iron ore was crushed in a jaw crusher. The average sizes of the feed ( F 80 ) and product ( P 80 ) were 50 and 10 mm, respectively. The energy consumed during

learn more

Rock breaker (a) at rest over ROM bin (b) breaking

Context 1 ... has been contracted by Rio Tinto Iron Ore to install a tele- robotic control system to the primary rockbreaker at the West Angelas mine, situated over 1000km north-east of Perth...

learn more

Crusher - an overview ScienceDirect Topics

The crusher product is ground in an SAG or AG mill (Giblett, 2019). AG mills crush the ore without the need for iron or steel grinding media. They are used when the ore is hard

learn more

Grizzly Screen - Mining Technology

Products Services. AViTEQ grizzly screens are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker, or as

learn more

Roller crushers in iron mining, how does the degradation of

2021年4月1日 Currently, in the mining process, roller crushers have been playing an important role due to their high productivity displayed in iron ore mining, as an example is

learn more

IRON ORE STEEL McNally Sayaji

Grizzly Screens. Grizzly Screens are used in primary crushing operation in Iron Ore Mining as scalping screen in downstream of the Primary Ore Crusher to separate undersized

learn more

A Mine-to-Crusher Model to Minimize Costs at a

2022年8月18日 The primary crushers are four mobile roller crushers (PF 200–9500) with the feed size between 0.80 m to 1.20 m and a maximum product size of 0.35 m; the crushed ore is transported through a system

learn more

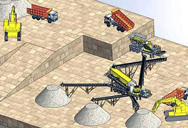

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

learn more

IFE Heavy-Duty Grizzly Feeders - Mining Technology

Applications for IFE grizzly feeders vary from chromate ores, iron ores, aggregates to CD waste. They are also capable of handling the highest capacities. Feed material with sizes up to 1,000mm and feed rates of more than 5,000tph for iron ore can be fed to a cone crusher, where the scalper removes fines below a cutpoint of 100mm.

learn more

Crushing - Metso

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. The high-capacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications. ... crusher parts, maintenance and optimization services. From large ...

learn more

en/iron ore crusher grizzly coal russian.md at main

Contribute to dinglei2022/en development by creating an account on GitHub.

learn more

Crushing Systems - FLSmidth

2020年4月15日 applications and are often the preferred choice in iron ore, coal and bauxite applications. Design ABON sizers are built using the highest quality components and highest design standards. This combination results in a robust design and a dedicated customer base. Performance Low Speed Sizing is one of the more unique crushing

learn more

China Cone Crusher, Jaw Crusher, Feeder Crushing

Shenyang New Haibo Machinery Co., Ltd: Chinese crusher manufacturer since 1999, the real alternative to the OEM! Home; About Us. Our History; Our Factory; Our Product; Product Application; Our Certificate; ... Grizzly Feeder 300tph. Model: ZSW1248 Feeding area: 4800X1170 mm Max. feeding: 650mm Capacity: 400tph.

learn more

McLanahan Types of Feeders and Their Applications

2021年2月9日 Grizzly bars on a Vibrating Grizzly Feeder allow fine material to pass through ahead of the crusher. Vibrating Pan Feeders. Vibrating Pan Feeders are generally used to feed primary crushers in aggregate, mining and recycling applications, but they can also be used to feed grizzly feeders for removing material ahead of a crusher.

learn more

BREAKING BAD: Rockbreaking equipment does the bull work

2017年4月14日 BTI, an Ontario-based manufacturer of rockbreaker systems – including stationary and mobile rockbreakers, hydraulic breakers, attachments and mobile equipment – offers hydraulic breakers in ...

learn more

en/crusher grizzly rock.md at main jidafang2022/en

Contribute to jidafang2022/en development by creating an account on GitHub.

learn more

Crusher Equipment Africa - Crusher Equipment Africa

2023年10月19日 Jaw Crusher. CE Africa series Jaw Crushers are mainly applied to coarse crushing in mine and aggregate industries, with the processing capacity ranging from 60 to 1,500t/h as coarse crushing when cooperating with CE Africa’s series grizzly feeders, so it can meet the requirements of small and middle-large size coarse crushing in most cases.

learn more

Grizzly crusher for sale, Price, Supplier, Spec - Dingli Mining

ZSW series vibrating grizzly feeder for sale price which can send materials to crusher continuously Shibang Industry Technology Group Co., Ltd. Price: US $700.00-$3000.00

learn more

grizzly Archives - International Mining

2021年5月18日 The importance of optimising blast parameters to reduce the cost of comminution and cut back on energy use is often stressed across the industry, but effective blasting can also reduce the likelihood of crusher obstructions, Motion Metrics says. Most unplanned plant downtime is crusher-related and primarily due to blockages caused by

learn more

Crushing and Grinding Wet Sticky Ore - 911

2016年5月9日 The fines from the grizzly and the crusher discharge pass by gravity and/or conveyor to a Combination Scrubber and Trommel. Here, further scrubbing and washing takes place to separate the ore into two

learn more

fr/grizzly crusher iron ore spécifications.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

learn more

Crushers - QueensMineDesignWiki

2019年6月28日 At the bottom of the hopper there is a grizzly. The grizzly is responsible for preventing over size material from entering the ore passes and the crusher where the material is liable to do damage to the equipment and underground construction. A standard opening for the grizzly, as defined by McIntosh Engineering, is ±16 by 18 inches.

learn more

Grizzly Feeder Manufacturer Propel Industries

PAN FEEDER. Propel Pan Feeders are designed for high capacity feeding especially for primary, secondary and tertiary duties. This simple but solid feeder is ideal for... Propel Grizzly Feeder can handle large feed rates with coarse blasted rock and also the material impact from dump trucks or wheel loaders. Learn More!

learn more

Crusher - an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

learn more

IRON ORE STEEL McNally Sayaji

Grizzly Screens. Grizzly Screens are used in primary crushing operation in Iron Ore Mining as scalping screen in downstream of the Primary Ore Crusher to separate undersized and oversized ore. Typical separation is at 80 mm.

learn more